Reducing Total Cost of Ownership: The Impact of Lubricants on Heavy-Duty Equipment

While lubricants themselves might only make up a small percentage of a heavy-duty off-road vehicle’s Total Cost of Ownership (TCO), their overall impact is far more significant. The correct, high-quality engine oils, cooling fluids, and greases will help reduce wear, improve fuel economy, and prevent costly downtime. Here, our in-house lubricant expert Johan Van Hove (Training Manager at Champion Lubricants) explains the importance of fluids and how they impact TCO.

When it comes to heavy-duty off-road fleets, managers understand and balance operational costs with operational efficiency. This is complicated by the economics of agriculture, construction, and mining, where every detail must be optimised to maximise productivity and profitability. Under these conditions, every saving counts. There is, however, one area that is often overlooked: lubrication.

On the surface, it is a simple decision, but the positive impact of purpose-formulated lubricants and fluids cannot be understated. Johan explains: “The amount spent on lubricants is minimal compared to the overall running costs of a vehicle. But using the wrong product can quickly lead to higher fuel consumption, faster component wear, and unexpected downtime.”

A small investment in better lubrication pays for itself many times over by reducing fuel use, protecting components and equipment, preventing downtime, and managing TCO.

Johan Van Hove

Senior Technical and Training Manager, Champion Lubricants

Analysing TCO: one per cent for maintenance

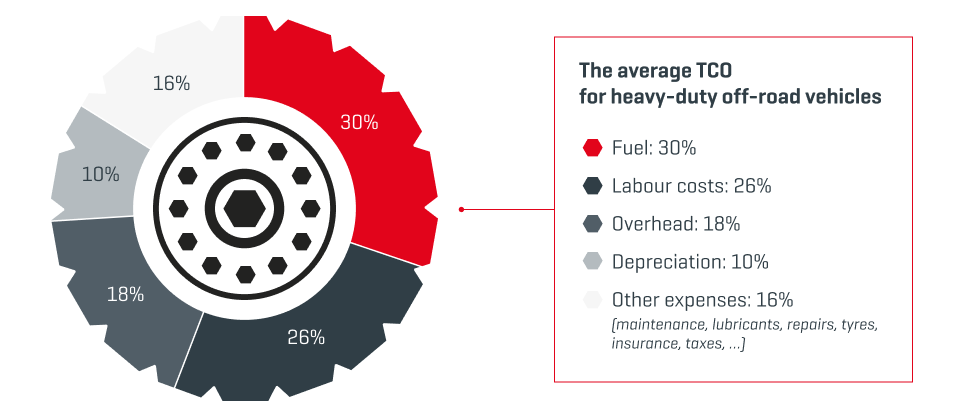

TCO provides a complete overview of what it really costs to operate and maintain a vehicle throughout its lifecycle. For heavy-duty off-road vehicles, such as trucks, Johan says: “Fuel represents the largest share at around 30 per cent of total cost. Labour accounts for about 26 per cent, and overhead expenses add another 18 per cent. Depreciation typically makes up around 10 per cent, while the remaining 16 per cent covers other expenses including tyres, insurance, taxes, lubricants, maintenance, and repairs.”

|

As you can see, of the 16 per cent attributed to ‘other expenses’, only around one per cent is for maintenance and around four per cent for repairs. So, in practice, lubricants and fluids are a very small fraction of overall costs.

“Looking purely at the numbers, lubrication seems insignificant,” explains Johan. “But poor lubrication choices often lead to higher fuel consumption, faster wear and more frequent repairs. Reducing lubricant quality or extending oil change intervals too far inevitably results in extra and unforeseen costs later on. This makes a relatively small investment in high-quality solutions extremely cost-effective.”

Small investment, large impact

Did you know that lubricant selection can have both direct and indirect effects on overall operational performance? Let’s look at some of the key factors…

- Improved fuel efficiency: Reduced friction leads to less energy loss

- Extended component life: Lower wear rates help protect costly parts

- Longer maintenance intervals: Reduced downtime and lower labour costs

- Greater reliability: Fewer unexpected breakdowns keep operations on track

- Better job planning: Predictable service schedules prevent production delays

“When you have downtime in heavy-duty off-road operations, it’s not just about idle equipment,” explains Johan. “It often means that crews are waiting or on standby, deadlines are being missed – all while operational complexity and associated risks are increasing. In many cases, effective lubrication management can play an important role in preventing the chain reaction of lost time and unforeseen costs.”

Johan continues, “Awareness of this issue remains too low within the HD off-road sector. This is because lubrication represents such a small percentage of the overall budget, leading many fleet managers to underestimate its impact. Unfortunately, some see it as an area to save a few cents per litre, but these short-term savings often lead to higher costs later on. Running high-quality fluids that are formulated for the purpose, with the latest innovative additives, is not a frivolous expense – it is an investment in reliability and productivity. It is about protecting the equipment and ensuring its performance. That is also where oil analysis can be an invaluable tool for informing predictive maintenance and better understanding how operational conditions are affecting the machines.”

Want to know more about our oil lab testing services? Explore LubeTrack

All fluids matter, but not equally!

Certain fluids have a more direct influence on operating costs than others. While this can vary depending on the type of vehicle, Johan has provided the following list as a general priority ranking:

“Although this order is indicative, every fluid contributes to equipment reliability and must meet the manufacturer’s specifications,” Johan explains. “Cutting corners, even on fluids considered less critical, can increase wear and reduce performance.”

Champion offers a comprehensive range of lubricants specifically formulated for heavy-duty off-road equipment. The XRS range includes engine oils, driveline and hydraulic fluids, greases, and coolants. “Additionally, we provide expert support to help fleet operators select the correct product for each application,” adds Johan. “We also have a digital recommendation tool that makes it quick and straightforward to identify the fluid you need, based on OEM requirements.”

Lower the TCO of your heavy-duty off-road fleet

Johan concludes: “Choosing high-quality fluids is actually one of the most important management decisions you can make. They support cooling, cleaning, corrosion protection, sealing, and even noise reduction. That’s not to mention the knock-on effects these characteristics have on reliability – protecting components, preventing unplanned downtime, and helping to control Total Cost of Ownership. That is why we developed the dedicated XRS range of lubricants and fluids for heavy-duty off-road applications. It is an efficient and effective route to access groundbreaking lubricants that are truly fit for purpose.”