Why Total Base Number (TBN) Matters: Key to Protecting Heavy-Duty Engines

Selecting an oil with the required Total Base Number (TBN) for heavy-duty off-road applications is a relatively inexpensive decision, but its impact over the lifecycle of equipment can be substantial. Johan Van Hove, Champion Lubricants Technical Manager, explains why TBN is key to protecting engines and reducing wear, downtime, and maintenance costs in heavy-duty machinery

“The Total Base Number (TBN) of an engine oil tells us how effectively the oil can neutralise acids formed during combustion,” explains Johan. “These acids depend on the sulphur content of the fuel and on how complete the combustion process is. To prevent acid-related corrosion and engine damage, it is vital to use an engine oil with an adequate TBN value. This makes TBN a critical factor when assessing an oil’s performance and suitability for heavy-duty applications.”

Low Total Base Number (TBN) means reduced engine protection

TBN is measured in milligrams of potassium hydroxide per gram of oil (mg KOH/g). It indicates how much alkaline reserve an engine oil has to neutralise acids that develop from fuel combustion. These acids, particularly sulphur-based compounds, can be extremely corrosive if not properly controlled within the engine.

“While TBN is not the only performance indicator for engine oil, it is a key one for heavy-duty engines,” continues Johan. “For example, a conventional new engine oil will have a Total Base Number between 6 and 13 mg KOH/g. Whereas heavy-duty applications start with a TBN of around 10, and anything above 13 is considered high. Basically, a higher TBN means greater acid-neutralising capacity, which is vital for protecting engine components such as pistons, bearings, and liners from corrosion and wear – especially in off-road machinery that operates under extreme conditions.”

“Basically, a higher TBN means greater acid-neutralising capacity, which is vital for protecting engine components.” Johan Van Hove, Senior Technical and Training Manager, Champion Lubricants

How additives impact TBN

“Engine oil typically consists of two main components: base oil, which accounts for about 80% of the total volume, and specific additives, which make up around 20%, depending on the oil type and application. Within that 20%, TBN forms part of a performance additive package that includes other components designed to boost engine protection. So, what is it? Well, TBN additives are comprised of detergents that neutralise acids, and despite their importance, they only represent a small percentage of the formulation and cost.”

"Selecting an oil with the required TBN for heavy-duty off-road applications is a relatively inexpensive decision, but its impact over the lifecycle of equipment can be substantial.” Johan Van Hove, Senior Technical and Training Manager, Champion Lubricants

What causes TBN depletion in engine oil?

“TBN levels in engine oil drop over time because the oil is actively neutralising acids,” Johan explains. “The main factor driving this depletion is fuel quality, particularly the sulphur content. Other influences include engine design, injection technology, operating temperature, and whether the engine runs continuously or intermittently. Modern fuels generally contain less sulphur, which reduces acid formation and helps preserve TBN for longer. However, in demanding environments such as agriculture, construction, and mining, depletion can still occur more rapidly due to harsh and variable operating conditions.”

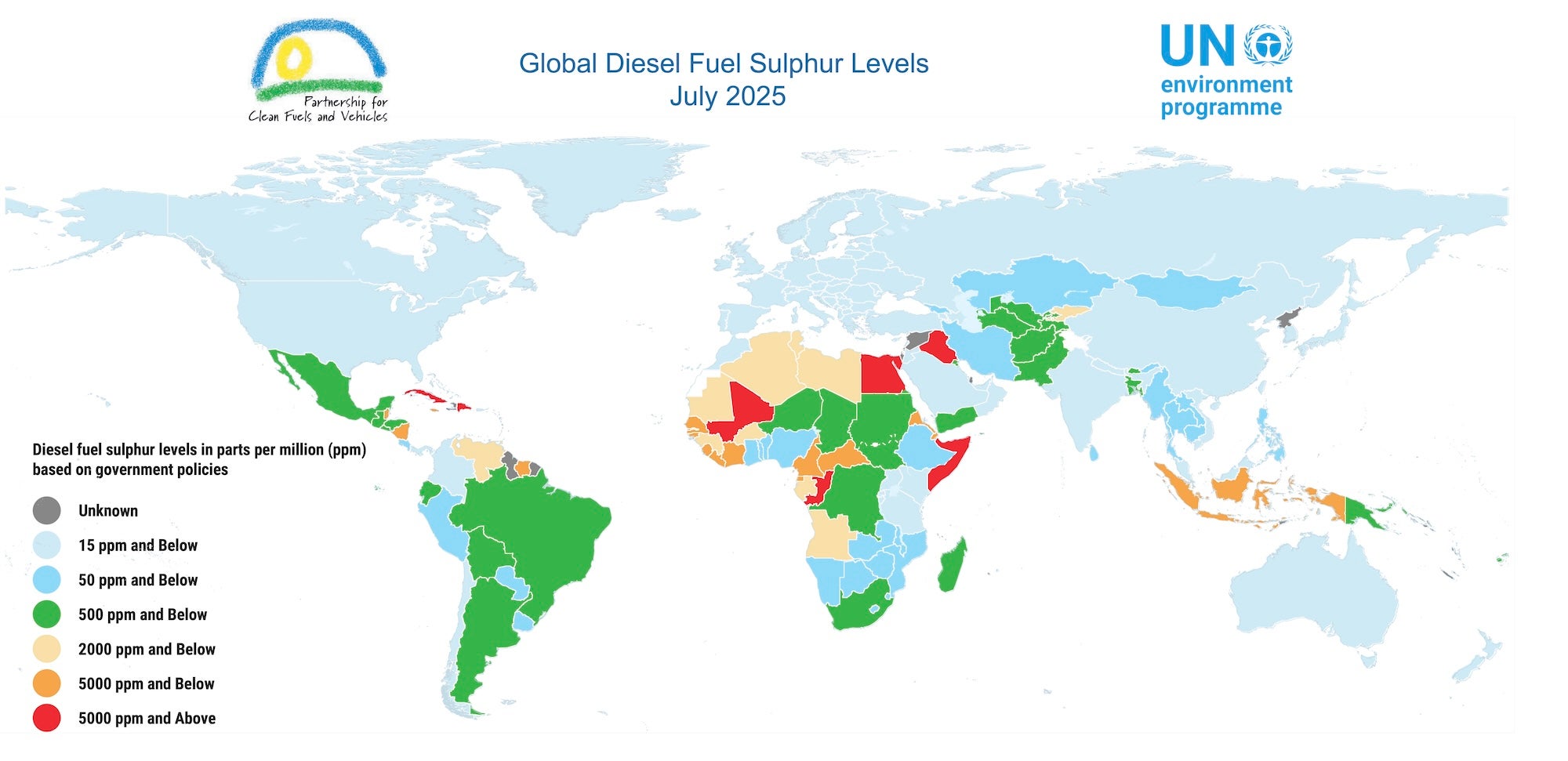

When are high TBN oils ‘worth it’?Higher TBN levels provide the greatest benefit in regions where fuel quality is lower and sulphur content is higher. This includes parts of Africa, Asia, Russia, South America, and the Middle East. Oils with high TBN also offer additional protection in areas where maintenance intervals are extended or unpredictable, such as remote mining or agricultural operations in Australia and the Americas, or in harsh working conditions with extreme temperatures and heavy dust exposure. “As an example, let’s look at Africa on this map,” explains Johan. “You can see that many countries across the continent continue to operate with diesel sulphur levels above 500 ppm, and in some cases between 2,000 and 5,000 ppm. When sulphur burns, it forms acidic by-products that accelerate oil degradation and engine wear. Combined with heat, dust, and limited access to servicing, these conditions make high-TBN oils essential. They neutralise excess acids, maintain oil stability, prevent corrosion, and ensure engines continue performing reliably between service intervals.”  Source: UN Environmental Program, https://www.unep.org/global-sulphur-levels, 2025 |

How can fleets monitor oil TBN?

“Here’s the thing: you can’t estimate remaining TBN by sight, smell, or oil colour,” explains Johan. “It must be measured through laboratory analysis. For heavy-duty applications such as agricultural, construction, and mining equipment, we recommend taking oil samples every 250 to 500 operating hours, depending on load, temperature, and humidity. Regular oil monitoring and analysis is the only reliable way to detect early signs of accelerated depletion and prevent unexpected downtime.”

Champion collaborates with POLARIS Laboratories®, which applies the ASTM D2896 method to accurately determine TBN levels. Laboratory turnaround time is typically one to two business days. As a general guideline, engine oil should be replaced once TBN reaches around 25% of its original value. The lab defines 25% remaining TBN as ‘Severity 3’.

“If you want to catch TBN depletion before it becomes an issue, regular oil monitoring and oil analysis are the only solution.” Johan Van Hove, Senior Technical and Training Manager, Champion Lubricants

Can you top up TBN with additive packages?

“This is a question that comes up occasionally,” explains Johan. “When we formulate engine oils, the additive packages are very precisely balanced for that exact specification and its associated applications. The addition of external additives can create compatibility issues. In turn, they may have the exact opposite effect, speeding up engine oil degradation and offering less protection than the original oil.”

Want to know more about our oil lab testing services? Explore LubeTrack

Remember to prioritise TBN

TBN may represent a small part of an engine oil’s formulation, but its impact is significant. While it might appear to be just another laboratory value, it plays a crucial role in determining oil life, preventing wear and corrosion, and controlling overall operating costs. With regular oil analysis and timely replacement, fleet managers can minimise unplanned downtime, extend drain intervals, and lower the Total Cost of Ownership.

“If your operations depend on engines, ensure they get robust protection – monitor your TBN!” Johan Van Hove, Senior Technical and Training Manager Champion Lubricants

TBN advantage: Champion Lubricants

With a TBN of around 10 considered standard for heavy-duty applications, Champion takes protection a step further. Our high-performance engine oils are developed specifically for demanding operations in agriculture, construction, mining, and infrastructure projects. Thanks to their elevated TBN values, these formulations deliver maximum protection under tough conditions and in regions where fuel quality is lower.

If you want to ensure that your engines are reliable in adverse conditions, select a Champion Lubricants solution for your heavy-duty off-road fleet.